Tire Technology: Grip, Efficiency, and Durability

Tires are a critical component of any vehicle, acting as the sole point of contact with the road. Far more than just rubber rings, they embody sophisticated engineering and material science, constantly evolving to meet the demands of modern automotive, transport, and mobility. Understanding the advancements in tire technology is essential for appreciating their profound impact on vehicle performance, fuel efficiency, safety, and overall driving experience across all types of vehicles, from cars to trucks and motorcycles.

How Tire Grip Influences Automotive Safety and Driving Dynamics?

Tire grip is fundamental to automotive safety and directly impacts a vehicle’s driving dynamics. It is the friction generated between the tire’s contact patch and the road surface that enables acceleration, braking, and steering. Advanced tire technology focuses on optimizing this grip through meticulously engineered tread patterns and specialized rubber compounds. Tread patterns are designed to channel water away from the contact patch, preventing hydroplaning in wet conditions, while also providing biting edges for traction on snow or ice. Rubber compounds are formulated with specific polymers and additives to achieve desired levels of adhesion, responding differently to varying temperatures and road surfaces to ensure reliable control and responsiveness during driving.

Enhancing Fuel Efficiency and Mobility Through Tire Design

Fuel efficiency and overall mobility are significantly influenced by tire design, particularly concerning rolling resistance. Rolling resistance is the force opposing a tire’s motion, and minimizing it can lead to substantial reductions in fuel consumption for traditional vehicles and extended range for electric and hybrid vehicles. Modern tire engineering employs lightweight construction materials, optimized internal structures, and advanced rubber compounds that deform less under load and generate less heat. This focus on efficiency not only contributes to economic benefits for drivers but also aligns with broader environmental goals by reducing emissions and energy consumption across the transport sector.

Factors Contributing to Tire Durability and Maintenance

Durability is a key aspect of tire technology, directly affecting a tire’s lifespan and the long-term maintenance costs for vehicle owners. Tire construction involves multiple layers, including plies and steel belts, which provide structural integrity and resistance to punctures and impacts. The rubber compounds used are engineered not only for grip and efficiency but also for wear resistance, ensuring the tire maintains its performance characteristics over many miles of travel. Proper maintenance, such as regular tire pressure checks, rotations, and wheel alignments, plays a crucial role in maximizing a tire’s durability, preventing premature wear, and ensuring consistent performance throughout its service life. This attention to maintenance is vital for all vehicles, from robust trucks to nimble motorcycles.

Tire Technology for Diverse Vehicles and Transport Needs

Tire technology is highly specialized to meet the unique demands of various vehicles and transport applications. Passenger cars often use all-season, summer, or winter tires, each designed for specific climatic conditions and driving styles. Trucks require heavy-duty tires capable of carrying substantial loads, with tread designs optimized for traction and stability under stress. Motorcycles utilize tires with distinct profiles that allow for extreme lean angles and provide precise handling. The rise of electric and hybrid vehicles has also spurred the development of specialized tires that can handle instant torque, offer lower rolling resistance for extended range, and provide quieter operation to complement the vehicles’ silent powertrains. This continuous innovation ensures that every vehicle benefits from tires tailored to its specific engineering and operational requirements.

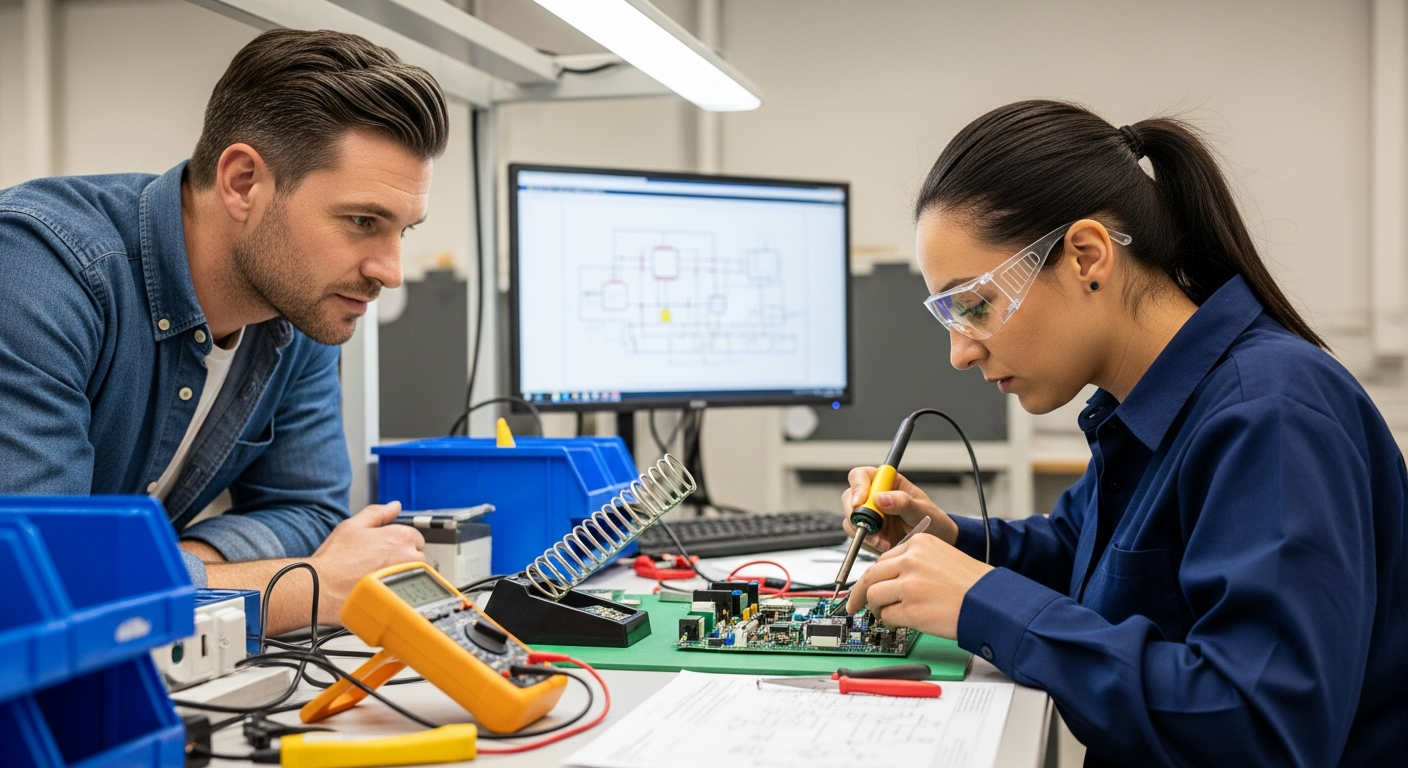

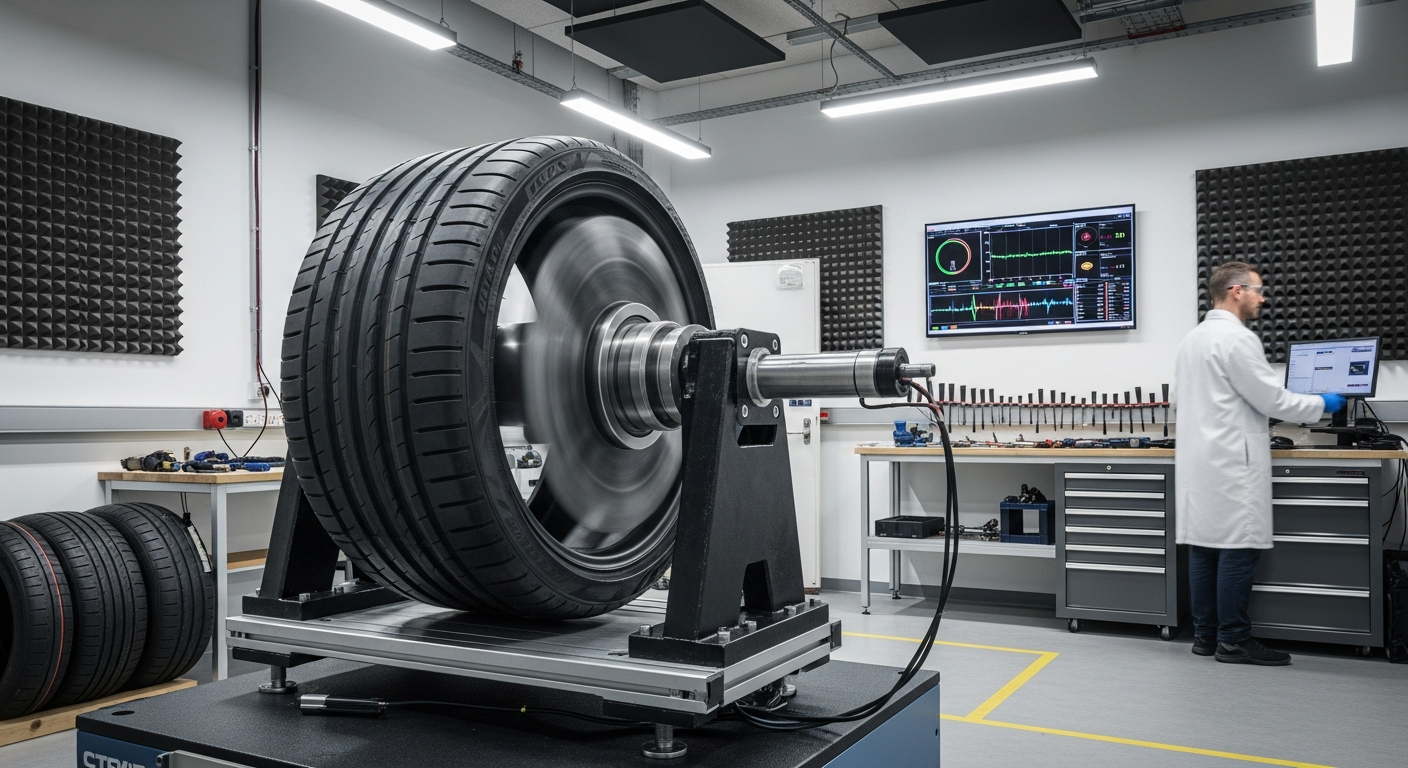

The Role of Tire Manufacturing and Road Interaction

The manufacturing process of tires is a complex sequence of mixing raw materials, building the tire’s structure, and curing it under heat and pressure to create a robust and high-performance product. Stringent quality control measures are integrated at every stage to ensure consistency and safety. The interaction between tires and various roads is a critical consideration in their design. Whether navigating dry asphalt, wet highways, snowy roads, or challenging off-road terrains, tires must adapt to provide optimal grip, stability, and comfort. Engineering teams continuously research and develop new technologies to enhance this interaction, ensuring reliable performance under a wide range of travel conditions and contributing to the overall safety and reliability of modern transport systems.

Tire technology represents a sophisticated blend of material science, mechanical engineering, and design innovation. From enhancing grip for paramount safety to optimizing rolling resistance for fuel efficiency and extending durability through advanced construction, tires are integral to the performance and functionality of all vehicles. The ongoing evolution in tire design continues to drive improvements in automotive capabilities, contributing significantly to a safer, more efficient, and more sustainable future for global mobility and driving experiences.